Manage, Comply, and Grow Your Food Business with Sage X3 Food and Beverage ERP Software

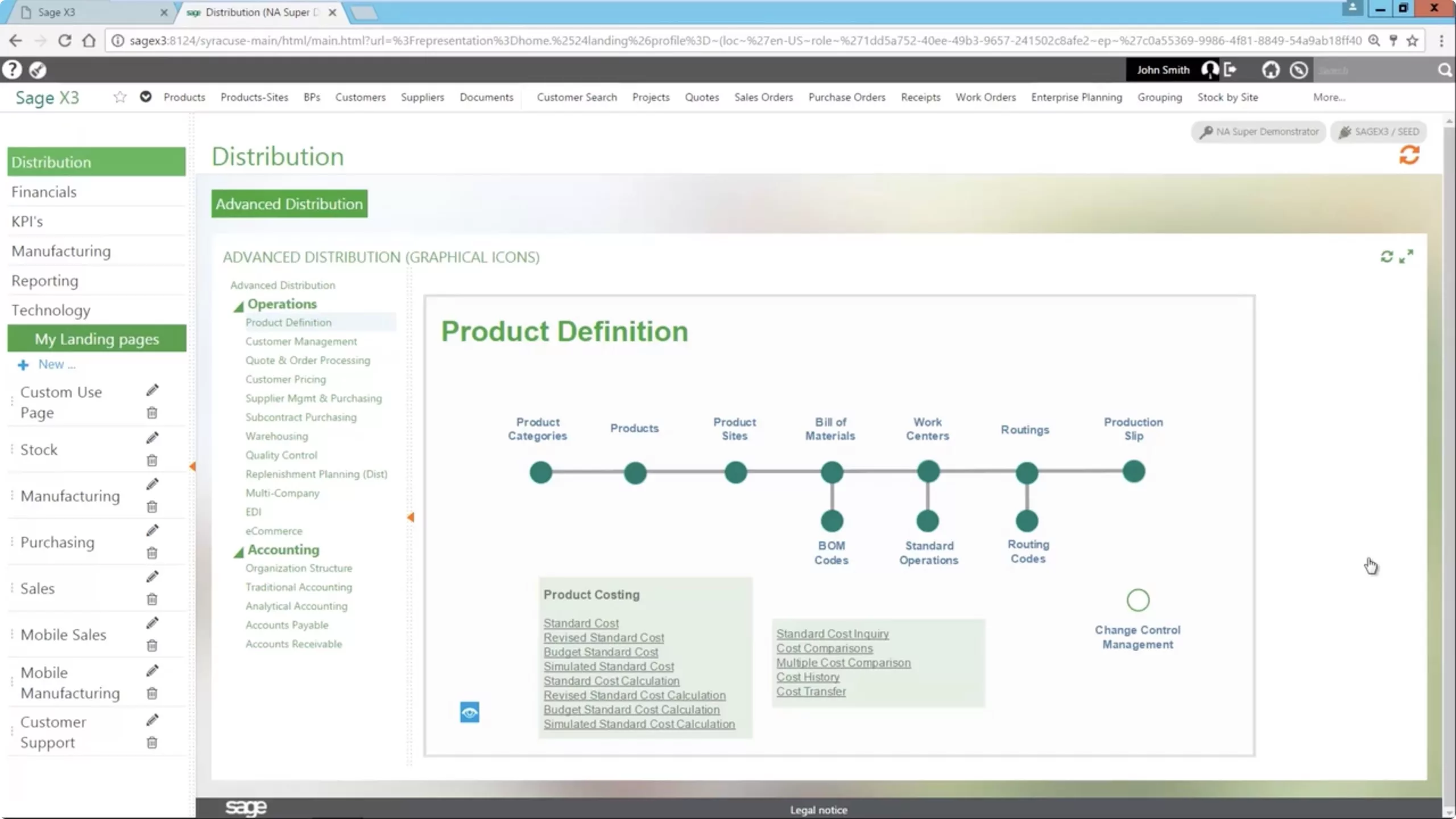

Designed for the food and beverage industry, our Sage X3 food and beverage ERP software helps you remain competitive and stay compliant with built-in capabilities such as recipe management, quality control, regulatory compliance, and lot tracking.

Compared to traditional distribution industries, the food and beverage industry has additional challenges of strict compliance, the possibility of recalls, consistency in supply and demand, and accountability while keeping costs down. Panni, with Sage X3, has successfully deployed best-in-class systems for its clients.

Built for food and beverage companies, Sage X3 provides vital information for making important business decisions and provides it quickly. The software’s robust core functionality enables companies to easily streamline compliance and eliminate inefficiency, providing a significant advantage over legacy systems and other less powerful ERPs.

Tailored Sage X3 Food and Beverage ERP Solutions for Your Unique Industry Needs

Browse our ERP Solutions by Industry Segment

Food Beverage ERP Software Capabilities for The Food & Beverage Industry

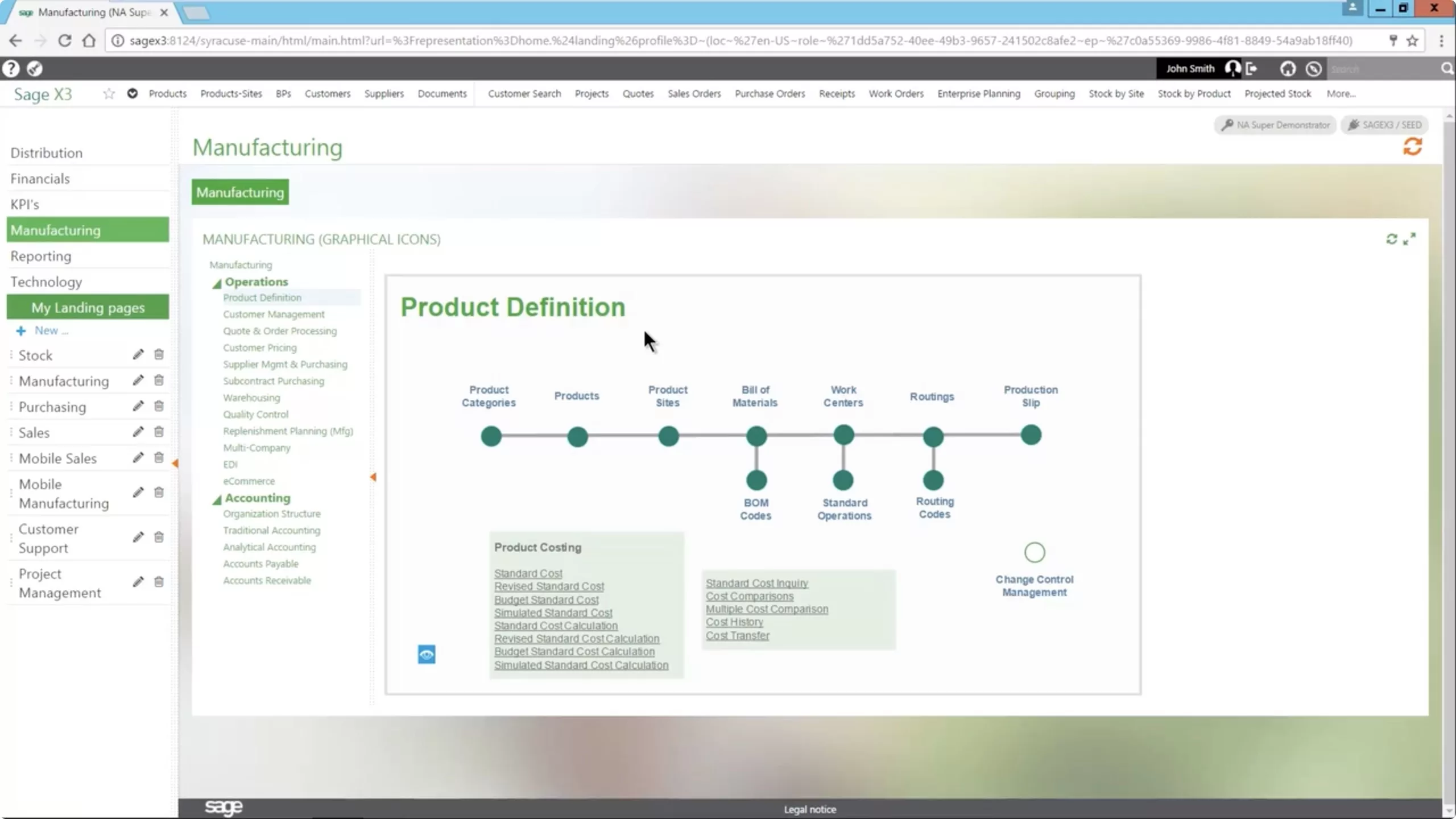

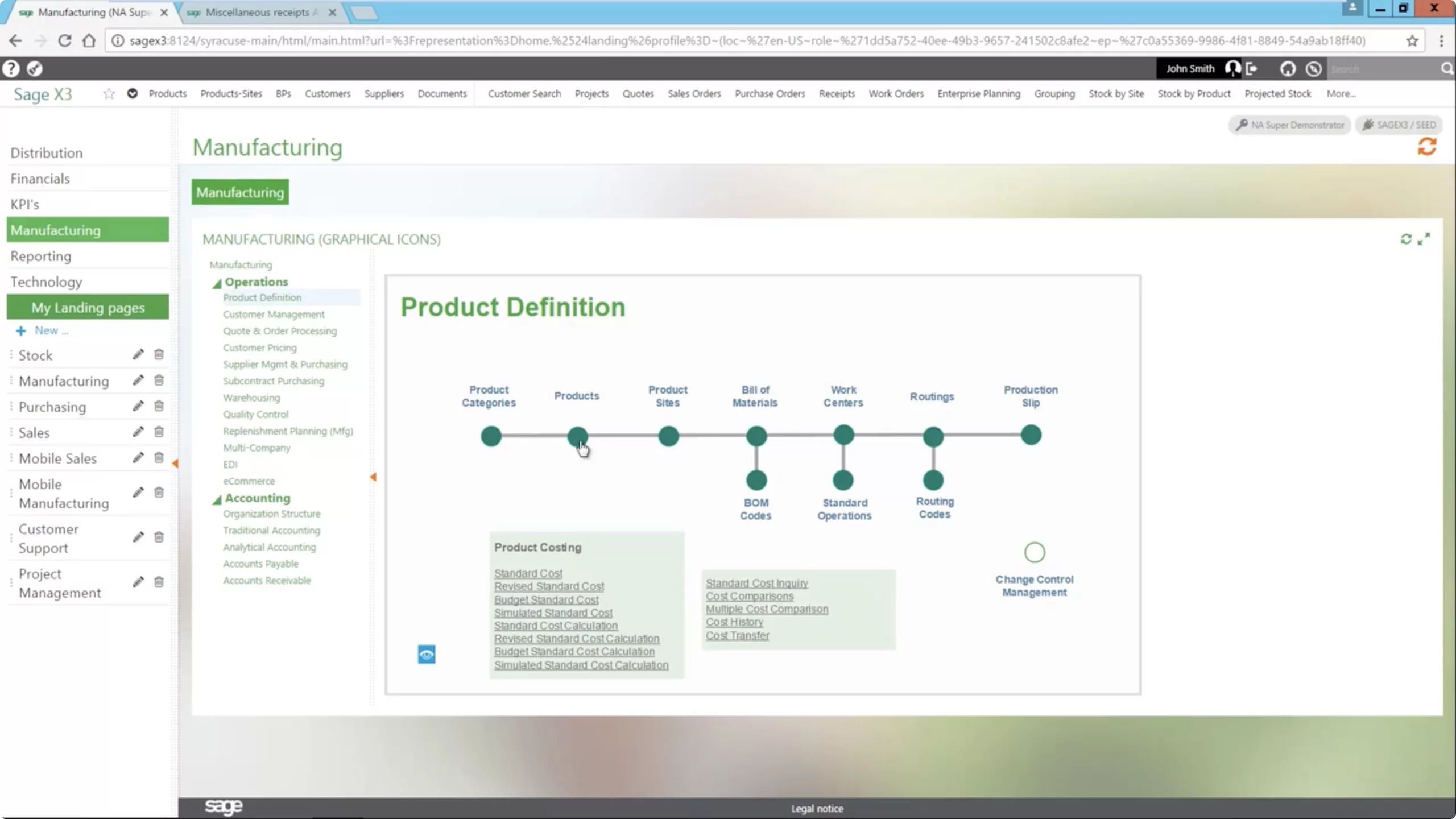

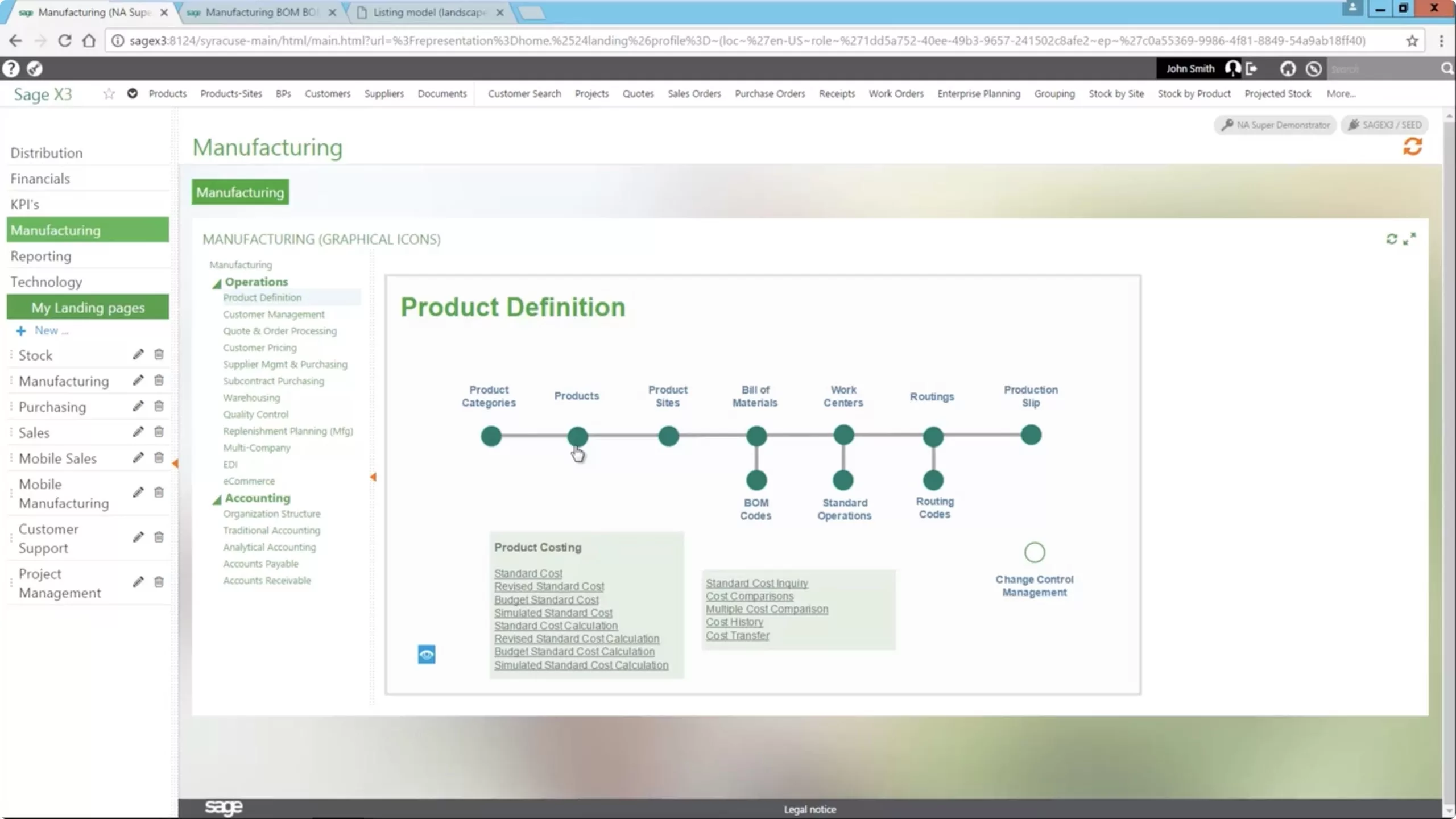

Sage X3, our choice of solution for the industry, delivers a specialized food and beverage solution using pre-defined business rules and processes together with a superior user experience that leads the market. Built to manage both front and back-office operations, Sage X3 runs entirely in the browser and across any device.

- Lot tracking and traceability

- Batch production

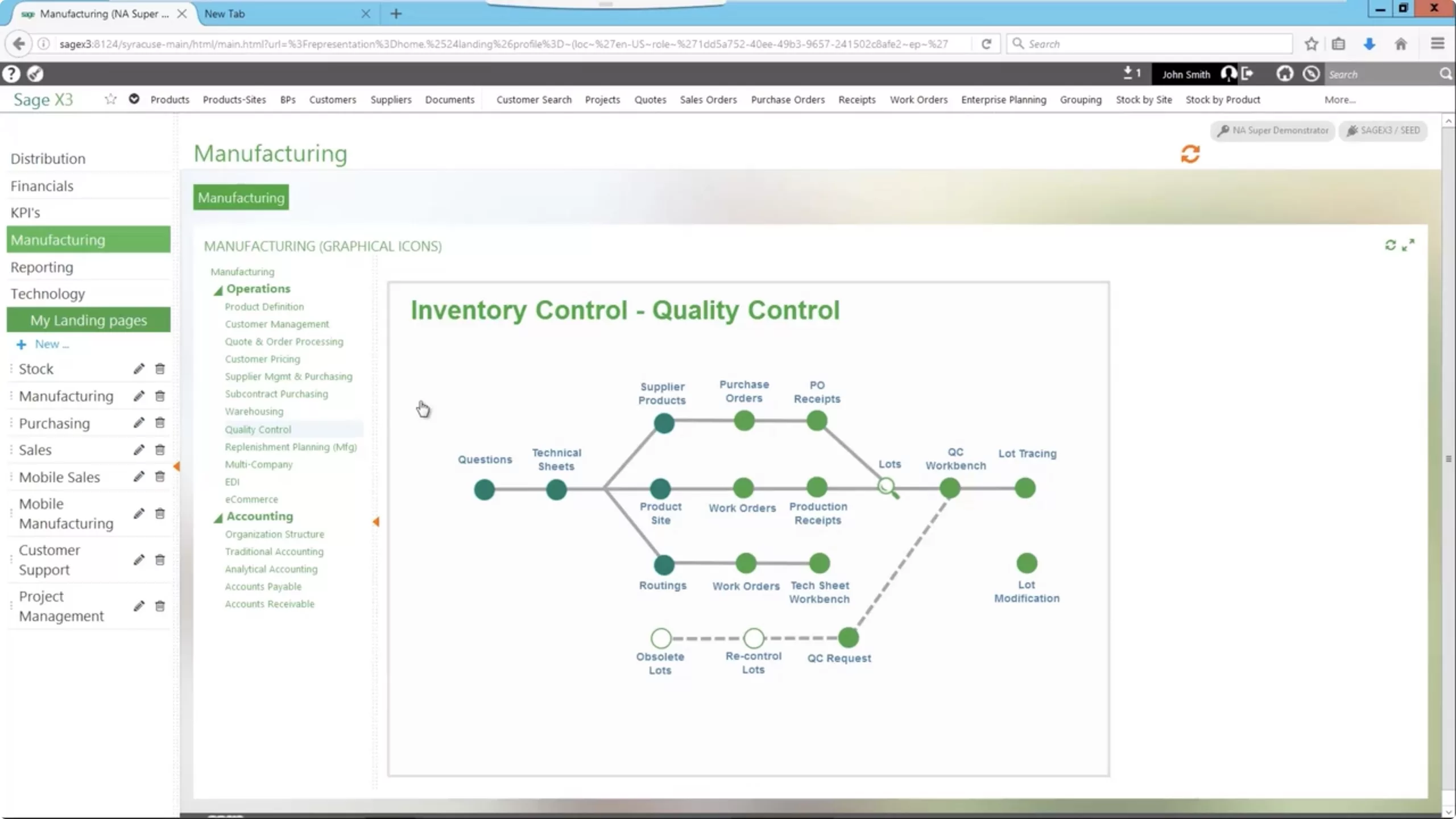

- Quality management

- Formula and recipe management

- Regulatory compliance and reporting

- Planning and scheduling

- Inventory management

- Single and multi-site management

- Role-based workspace

- Workflow automation and alerts

- Reporting and business analytics

- Mobility tool-kit

Read our Customer's Success Story

Erin Baker’s Obtains Real Process and Cost Efficiencies with Panni and Sage X3

Erin Baker’s was rapidly growing and needed a robust tech solution to better manage their operations. They had extensive needs that varied across the organization; managing their financials, manufacturing processes, credit card management, quality assurance, cost analysis and custom reporting to name a few.

The Erin Baker’s team saw instant results which enabled them to not only run a more efficient operation on the backend but also provide a more streamlined service to their customers.

Designed Specifically for Food & Beverage: Sage X3 Food and Beverage ERP Solutions

Product Traceability

Sage X3’s strong traceability tools allow better handling of recalls, expiration management, sustainability, allergen-free production, labeling, and other major trending concerns. As your business grows and requirements change, Sage X3 adapts to help you meet new requirements without increasing overhead.

Allergen Tracking

Tracking allergens in finished goods and raw materials is a major requirement for the food and beverage industry. The Food Safety Modernization Act in the USA and the Safe Food for Canadians regulations both require stringent tracking, monitoring and disclosure of allergens in the sector.

Recipe Management

Control

All recipes are stored in the recipe records list. In addition, Sage X3 allows companies to maintain consistency and tight controls or recipes to prevent tampering by requiring approval at different stages of development.

Version management

Sage X3 also supports version management of recipes to allow for the improvement of recipes, fulfill specific customer needs, or alternate ingredients.

Scalability

To cut costs recipe management also enables scalability of finished products. Users can adjust calculated totals and see the BOM quantity change as well as the total ingredient costs. With recipe management in Sage X3 food and beverage, your business can be sure to create quality and consistent products for your consumers

Food and Beverage Product Tour Videos

Allergen tracking in Sage X3

Percent Scrap setup in Sage X3

Traceability in Sage X3

What our Customers Say

Sage X3 Features Videos for Food and Beverage Industry

General capabilities and video series overview

Lot management

Date expiration with Use-by date control

Allergens and quality control

Quality control

FSMA and HACCP collaboration

Our Featured Customers

*commissioned Forrester Total Economic Impact™ study.

Sage Business Cloud is changing how businesses compete and grow by delivering faster, simpler and flexible financial, supply chain and production management at a fraction of the cost and complexity of typical enterprise ERP systems.

With Sage Business Cloud X3, you are choosing the next generation business management solution for your enterprise to grow faster and run an agile organization.

Your privacy is important to us. We will never sell, rent, or give away your contact information.